Understanding Box Girder Bridge Cranes: Pros, Cons, and Applications

Box girder bridge cranes are a crucial type of overhead crane commonly used in industries requiring heavy-duty lifting solutions. These cranes are characterized by their box-shaped girders, which provide immense strength and stability, making them ideal for handling large loads. In this blog, we will dive deep into what box girder bridge cranes are, their advantages and disadvantages, and why they may be the best option for your facility over other crane types.

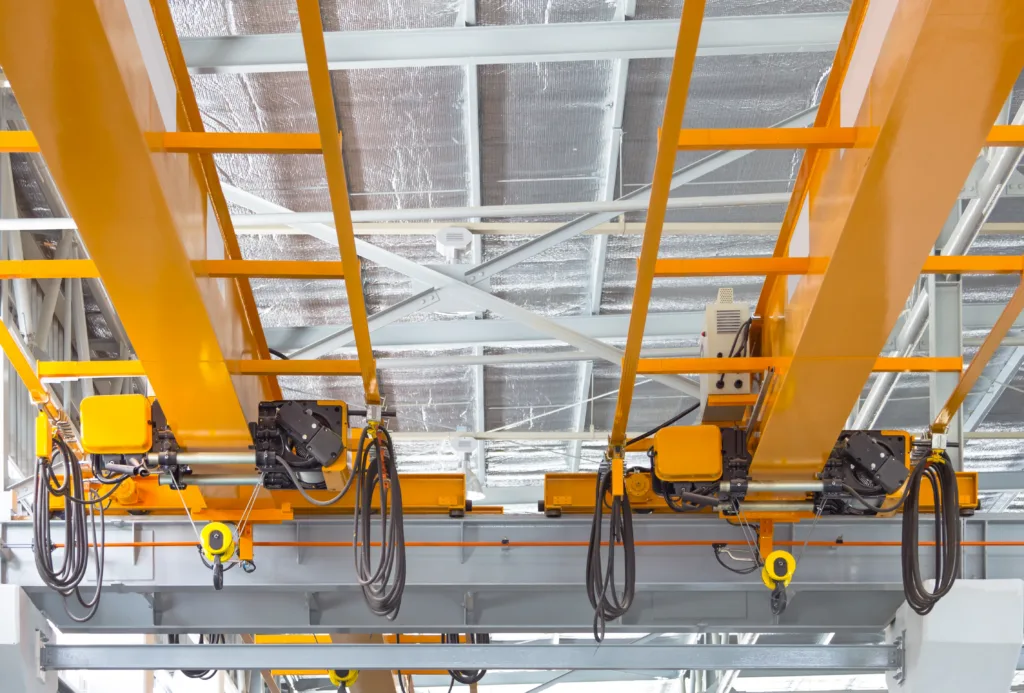

What are Box Girder Bridge Cranes?

Box girder bridge cranes are a specific type of bridge crane where the main girder used for supporting loads is enclosed in a box shape. The design involves four plates that are welded together to form a rectangular, hollow box, as opposed to other cranes that may use I-beams or H-beams. This box structure provides high levels of rigidity and strength, which allows the crane to carry exceptionally heavy loads across large spans.

These cranes are often found in environments such as:

- Steel plants

- Shipyards

- Automotive manufacturing

- Warehouses

- Heavy engineering sectors

Key Applications of Box Girder Bridge Cranes

Due to their robust design, box girder bridge cranes are typically used in industries that demand:

- Heavy Lifting: These cranes can handle large-capacity loads, often reaching several hundred tons.

- Precise Positioning: The rigid structure provides excellent control and precision when moving materials.

- Long Spans: The box girder design can accommodate spans much longer than traditional cranes, making it ideal for wide industrial facilities or yards.

Why Use Box Girder Bridge Cranes Over Other Types?

When compared to other crane types, such as single girder cranes or I-beam-based cranes, box girder bridge cranes have several advantages:

1. Increased Load Capacity

The box girder design can handle much heavier loads than I-beam girders or single-girder cranes. This makes them the preferred choice for industries that require lifting and transporting extremely heavy objects, such as foundries or steel manufacturing plants.

2. Enhanced Stability and Rigidity

The closed box design provides excellent torsional rigidity, meaning it can resist twisting and bending under heavy loads or when operating over long distances. This stability ensures smooth and safe material handling, even in demanding environments.

3. Longer Spans and Greater Coverage

One of the significant benefits of box girder cranes is their ability to cover longer spans. In facilities that require moving materials across large areas, such as aircraft hangars or shipping yards, a box girder bridge crane can be the optimal solution because it can span greater distances without compromising strength.

4. Durability

Box girder cranes are built to last. Their robust design enables them to endure long-term use, heavy loads, and various industrial conditions. For industries that require constant material handling, box girder cranes offer durability and reliability that outmatch other types of cranes.

5. Precision and Control

These cranes offer better precision and control when compared to simpler designs. Their structure supports more sophisticated hoisting mechanisms, which allows operators to handle loads with higher accuracy.

Cons of Box Girder Bridge Cranes

While box girder bridge cranes have many benefits, they are not without their drawbacks. Some of the cons include:

1. Higher Initial Costs

Due to their complex design and the materials used in construction, box girder cranes tend to be more expensive upfront compared to single girder or I-beam cranes. However, this cost is often offset by the crane’s durability and extended lifespan.

2. Maintenance Costs

Although these cranes are robust, they can require more frequent and specialized maintenance due to the complexity of their design. Box girders need regular inspections to ensure that they remain free of fatigue cracks or other structural weaknesses, especially when operating under extreme loads.

3. Space and Installation Requirements

Box girder bridge cranes are larger and heavier than many alternatives. As a result, they require substantial support structures and larger clearances during installation. Smaller facilities or those with limited space may find this crane type impractical or difficult to accommodate.

Box Girder Cranes vs. Single Girder Cranes

The main alternative to a box girder crane is a single girder crane, which uses a single beam to support the hoist and trolley. Here’s a quick comparison between the two:

| Feature | Box Girder Crane | Single Girder Crane |

|---|---|---|

| Load Capacity | Higher, ideal for heavy-duty applications | Lower, suitable for lighter loads |

| Span Length | Longer spans, can handle large facilities | Shorter spans, better for compact spaces |

| Rigidity | Extremely rigid and stable | Less rigid, may flex under heavy loads |

| Initial Cost | Higher due to complex design and materials | Lower due to simpler design |

| Precision | High precision for sensitive material handling | Less precision, suitable for general applications |

Is a Box Girder Bridge Crane Right for Your Business?

Box girder bridge cranes are ideal for businesses that require heavy-duty, high-capacity lifting solutions over large spans. While they may come with higher initial costs, their durability, stability, and strength make them a worthwhile investment for long-term use in demanding environments.

If your business operates in an industry that frequently handles heavy loads, requires precise movement, or operates across large spaces, a box girder bridge crane could be the solution to optimize your workflow and improve efficiency. On the other hand, if your lifting needs are smaller-scale or more budget-conscious, a single girder or I-beam crane might be a better fit.

For more information on how Handling Systems International (HSI) can customize a box girder bridge crane to suit your specific requirements, visit our website or contact us directly.

Conclusion

Box girder bridge cranes stand out for their ability to handle heavy loads, long spans, and challenging industrial environments. While the initial investment may be higher, their durability and performance make them a superior choice for businesses requiring reliable and high-capacity material handling solutions.