Handling Systems International

Blog

Overhead Cranes 101: A Buyer’s Guide for Manufacturers

Box girder bridge cranes are a crucial type of overhead crane commonly used in industries requiring heavy-duty lifting solutions. These cranes are characterized by their box-shaped girders, which provide immense strength and stability, making them ideal for handling large loads. In this blog, we will dive deep into what box girder bridge cranes are, their advantages and disadvantages, and why they may be the best option for your facility over other crane types.

Box Girder Bridge Crane Applications

Box girder bridge cranes are a crucial type of overhead crane commonly used in industries requiring heavy-duty lifting solutions. These cranes are characterized by their box-shaped girders, which provide immense strength and stability, making them ideal for handling large loads. In this blog, we will dive deep into what box girder bridge cranes are, their advantages and disadvantages, and why they may be the best option for your facility over other crane types.

Jib Cranes VS. Davit Cranes

When comparing jib cranes and davit cranes, it’s important to understand their unique characteristics and applications. Let’s explore the key differences between these two types of cranes to help potential buyers make informed decisions.

Jib Cranes VS. Overhead Cranes

When comparing jib cranes to overhead cranes, it’s important to understand their distinct characteristics, applications, and advantages. Let’s explore the key differences between these two types of material handling equipment.

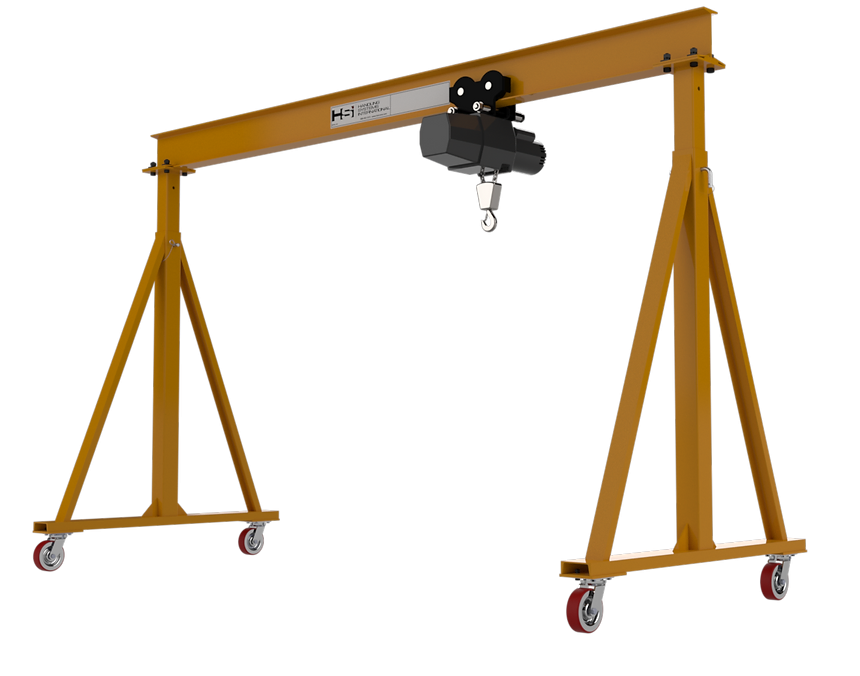

HSI Cranes: Understanding the Difference Between Jib Cranes and Gantry Cranes

At Handling Systems International (HSI), we pride ourselves on providing custom-built crane solutions to meet the unique lifting needs of our customers. Two popular types of cranes we offer are jib cranes and gantry cranes. While both serve essential roles in material handling, they have distinct characteristics and applications. Let’s explore the key differences between these two crane types. Jib Cranes: Versatility in Confined Spaces Jib cranes are characterized by their simple yet effective design. They consist of a horizontal boom attached to a vertical mast, allowing for rotational movement. Here are some key features of jib cranes: Jib cranes excel in applications requiring frequent lifting within a specific work area, such as assembly lines, loading docks, or maintenance bays Gantry Cranes: Power and Mobility Gantry cranes, on the other hand, are designed for heavy-duty lifting and broader coverage areas. They consist of a bridge supported by two or more legs that move along ground-level runways. Key features of gantry cranes include: Gantry cranes are commonly used in outdoor settings like shipyards and construction sites, as well as indoor facilities such as warehouses and manufacturing plants. Key Differences Choosing the Right Crane When selecting between a jib crane and a gantry crane,

Mastering Material Handling: A Comprehensive Guide to Electric Overhead Traveling (EOT) Cranes

Unpacking the Mechanics of Overhead Factory Cranes At Handling Systems International (HSI), we understand that the backbone of any efficient production, assembly, or logistics operation often relies on the adept handling of materials. Overhead Factory Cranes, commonly referred to as Bridge Cranes or Electric Overhead Traveling (EOT) cranes, are at the heart of these processes. Designed to optimize both space and time, EOT cranes are crucial for seamless material movement across various industrial scenarios. How EOT Cranes Operate in Industrial Settings An EOT crane typically operates along two parallel runway beams, effectively spanning the width of the workshop. This arrangement allows for what we call “down-shop” travel, facilitating the movement of goods along the shop’s length. To power these movements, electric power is transferred from a stationary source to the moving crane bridge, primarily through a Conductor Bar System aligned with the runway beams. While this is the most common method, alternatives like Cable Festoons, Cable Chains, or Cable Reels are also used depending on specific environmental needs or operational preferences. The energy from the runway conductors is transferred to the crane’s bridge, enabling the hoist trolley—or trolleys—to move perpendicularly to the runways. This movement is pivotal, positioning the hoist

Join Our Newsletter

Subscribe to stay up to date